How to Operate a Skid Loader?: Master the Basics

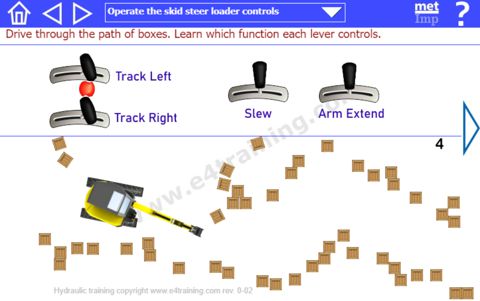

To operate a skid loader, enter the cabin, fasten your seatbelt, and familiarize yourself with the controls. Use the left joystick for steering and the right joystick for lifting and tilting the bucket.

Skid loaders are versatile machines used in construction and landscaping. They can easily maneuver in tight spaces, making them ideal for various tasks. Understanding how to operate a skid loader safely can enhance productivity and prevent accidents. Operators should always check the machine’s surroundings and ensure proper visibility before starting.

Familiarity with the controls boosts efficiency and reduces the risk of errors. Learning the basic functions and safety protocols is essential for both novice and experienced operators. With practice, you can master skid loader operation quickly and effectively.

Credit: en.wikipedia.org

Introduction To Skid Loaders

Skid loaders are versatile machines in the construction world. They have a compact design and excellent maneuverability. Skid loaders are crucial for digging, lifting, and transporting materials. Operators can easily control them in tight spaces. Understanding their features and types is essential for effective operation.

The Role Of Skid Loaders In Construction

Skid loaders play a vital role in various construction tasks. Here are some key functions:

- Excavating dirt and debris.

- Loading materials onto trucks.

- Clearing snow from roads and pathways.

- Grading and leveling surfaces.

- Transporting heavy items across job sites.

These machines enhance productivity and efficiency. They help complete tasks faster and with less labor.

Types Of Skid Loaders

There are several types of skid loaders available. Each type serves different purposes:

| Type | Description |

|---|---|

| Standard Skid Loader | General-purpose loader suitable for most tasks. |

| Compact Skid Loader | Smaller size for tighter spaces and delicate tasks. |

| High-Flow Skid Loader | Designed for heavy-duty attachments and larger loads. |

| Track Skid Loader | Features tracks instead of wheels for better traction. |

Choosing the right type improves work efficiency. Each skid loader offers unique advantages for specific jobs.

Safety First

Operating a skid loader involves risks. Prioritizing safety protects everyone on the job site. Follow these guidelines to ensure a safe working environment.

Personal Protective Equipment

Wear the right Personal Protective Equipment (PPE) to stay safe. Essential PPE includes:

- Hard hats: Protects your head from falling objects.

- Safety goggles: Shields your eyes from dust and debris.

- Ear protection: Reduces noise exposure.

- Steel-toed boots: Safeguards your feet from heavy loads.

- Gloves: Ensures a firm grip while operating.

Always inspect your PPE before use. Replace damaged gear immediately.

Understanding The Risks

Skid loaders can be dangerous. Be aware of the following risks:

| Risk | Description |

|---|---|

| Tip-overs | Skid loaders can tip on uneven ground. |

| Moving parts | Fingers or clothing can get caught. |

| Falling objects | Heavy materials may fall during operation. |

| Visibility issues | Blind spots can hide hazards. |

To minimize risks:

- Conduct a site assessment before operating.

- Use the loader on stable, flat surfaces.

- Always check surroundings before moving.

- Keep the loader’s load low for better stability.

Stay vigilant and communicate with your team. A safe workplace benefits everyone.

Pre-operation Checklist

Before operating a skid loader, complete a thorough pre-operation checklist. This ensures safety and proper functioning. Skid loaders are powerful machines. Checking them properly can prevent accidents and costly repairs.

Inspecting The Skid Loader

Start with a visual inspection of the skid loader. Look for any visible damage. Check for leaks or loose parts. Here are key areas to examine:

- Body: Look for dents or rust.

- Bucket: Inspect for cracks or wear.

- Hydraulic hoses: Check for leaks or damage.

- Lights: Ensure all lights are working.

Make sure the safety guards are in place. Check the operator’s seat for any damage. A safe working environment begins with a careful inspection.

Checking Fluid Levels And Tires

Next, check fluid levels. This includes:

| Fluid Type | Optimal Level |

|---|---|

| Engine Oil | Full |

| Hydraulic Fluid | Full |

| Coolant | Full |

Next, examine the tires. Ensure they are properly inflated. Look for any signs of wear. Here’s a quick checklist:

- Check tire pressure.

- Inspect tread depth.

- Look for cuts or punctures.

Proper fluid levels and tire conditions enhance performance. They also ensure safety during operation.

Starting The Skid Loader

Starting a skid loader is simple. Follow these steps to ensure safe operation. Knowing the correct procedures is crucial for efficiency and safety.

Key Ignition Steps

- Check the Area: Ensure the area is clear of obstacles.

- Enter the Cab: Climb in safely using the handrails.

- Secure the Seatbelt: Buckle your seatbelt for safety.

- Insert the Key: Place the key in the ignition.

- Turn the Key: Rotate the key to the “on” position.

- Start the Engine: Turn the key to start the engine.

- Check Gauges: Ensure all gauges are functioning correctly.

Control Panel Familiarization

Understanding the control panel is essential. Familiarize yourself with the following components:

| Control | Description |

|---|---|

| Throttle | Controls engine speed. |

| Joystick | Steers the skid loader. |

| Bucket Controls | Raises and lowers the bucket. |

| Parking Brake | Engages and disengages the brake. |

Each control has a specific function. Get comfortable using them before driving.

Basic Maneuvers

Operating a skid loader requires skill and practice. Mastering basic maneuvers is essential. This section covers driving, turning, and parking your skid loader.

Driving Forward And Reversing

Driving a skid loader is simple. Follow these steps:

- Adjust your seat and controls for comfort.

- Engage the safety features.

- Use the joystick to move forward.

To reverse:

- Pull the joystick back gently.

- Check your surroundings for safety.

Keep an eye on the front loader. It helps with visibility.

Turning And Parking

Turning a skid loader needs practice. Follow these tips:

- Slow down before turning.

- Use the joystick to pivot.

For parking:

- Find a flat area.

- Lower the bucket to the ground.

- Shift the loader into neutral.

Turn off the engine once parked. Always engage the parking brake.

Operating The Bucket

Operating the bucket of a skid loader is vital for effective work. Proper techniques ensure safety and efficiency. Mastering bucket operations can enhance your productivity significantly.

Lifting And Lowering

Lifting and lowering the bucket involves precise control. Follow these steps for effective operation:

- Engage the controls: Use the joystick for smooth movements.

- Lift the bucket: Pull the joystick back gently.

- Lower the bucket: Push the joystick forward slowly.

- Keep the load balanced: Ensure the weight is evenly distributed.

Maintain a safe height to avoid tipping. Always check surroundings before lifting.

Loading And Dumping Techniques

Proper loading and dumping techniques maximize efficiency. Use these tips:

- Positioning: Approach the load straight on.

- Loading: Tilt the bucket slightly forward while lowering.

- Fill the bucket: Use a smooth motion to gather material.

- Dumping: Raise the bucket and tilt back to release.

Practice makes perfect. Start with lighter loads. Gradually work up to heavier materials.

| Action | Control Method |

|---|---|

| Lifting | Pull joystick back |

| Lowering | Push joystick forward |

| Dumping | Raise and tilt bucket back |

Following these steps ensures safe and efficient bucket operations. Always focus on control and balance.

Advanced Operating Techniques

Mastering advanced operating techniques enhances your skid loader skills. These techniques allow for greater efficiency and safety. Two key areas to focus on include handling uneven terrain and working in tight spaces.

Handling Uneven Terrain

Driving on uneven ground requires special techniques. Follow these tips to improve stability and control:

- Maintain a Low Center of Gravity: Keep the loader’s bucket low.

- Use Cautious Speed: Slow down on slopes and bumps.

- Position Wheels Strategically: Align wheels with the slope direction.

- Balance Weight: Distribute weight evenly across the loader.

Always be aware of your surroundings. Watch for rocks, holes, and other obstacles. Use the loader’s tilt function to adjust the bucket angle. This helps maintain balance on slopes.

Working In Tight Spaces

Operating in confined areas poses unique challenges. Here are effective strategies for navigating tight spaces:

- Plan Your Path: Scout the area before moving.

- Use Slow Movements: Avoid jerky motions to maintain control.

- Utilize Corners: Pivot around corners to save space.

- Keep the Loader Compact: Retract attachments when possible.

Practice makes perfect. Spend time in controlled environments. This builds confidence and sharpens your skills. Remember to keep your surroundings in mind. Avoid obstacles and always check your blind spots.

Maintenance And Troubleshooting

Maintaining a skid loader is crucial for its performance and longevity. Proper maintenance helps prevent breakdowns and costly repairs. Knowing how to troubleshoot common issues can save time and keep projects on schedule.

Regular Maintenance Schedule

Establishing a regular maintenance schedule ensures your skid loader runs smoothly. Follow these essential maintenance tasks:

- Daily Checks: Inspect fluids, tires, and filters.

- Weekly Maintenance: Clean air filters and check battery connections.

- Monthly Tasks: Change engine oil and lubricate moving parts.

- Yearly Inspections: Conduct a full service, including hydraulic fluid replacement.

Use the table below for a quick reference:

| Maintenance Task | Frequency |

|---|---|

| Daily Checks | Every Day |

| Weekly Maintenance | Weekly |

| Monthly Tasks | Monthly |

| Yearly Inspections | Annually |

Common Issues And Solutions

Skid loaders can face various issues. Identifying problems early helps prevent bigger repairs. Here are some common issues and their solutions:

- Engine Won’t Start:

- Check battery connections.

- Inspect fuel levels.

- Examine starter motor for damage.

- Hydraulic System Failure:

- Check hydraulic fluid levels.

- Inspect hoses for leaks.

- Test hydraulic pump performance.

- Overheating:

- Clean the radiator.

- Check coolant levels.

- Inspect the fan for proper operation.

Regular checks can prevent these issues. Addressing problems quickly keeps your skid loader operational and efficient.

Best Practices For Efficient Operation

Efficient operation of a skid loader can save time and resources. Following best practices ensures smooth workflow and energy conservation. Proper techniques enhance both productivity and safety.

Optimizing Workflow

To maximize your skid loader’s efficiency, implement these strategies:

- Plan Your Routes: Map out tasks before starting.

- Keep the Area Clear: Remove obstacles from the work site.

- Use Attachments Wisely: Select the right attachment for each task.

- Limit Repetitive Movements: Organize tasks to reduce back-and-forth trips.

Consider using a checklist to ensure all tasks are efficient. This can help in tracking progress and identifying areas for improvement.

Energy Conservation Tips

Conserving energy while operating a skid loader is essential. Here are some effective tips:

| Tip | Description |

|---|---|

| Use Idle Time Wisely | Turn off the engine during long breaks. |

| Maintain Proper Tire Pressure | Check tire pressure regularly for better fuel efficiency. |

| Reduce Speed | Drive at a steady speed to save fuel. |

| Schedule Regular Maintenance | Keep your machine in top shape for optimal performance. |

Implement these energy-saving tips to reduce operating costs and environmental impact. Small changes can lead to significant savings.

Credit: www.e4training.com

Credit: www.mylittlesalesman.com

Frequently Asked Questions

How Do I Start A Skid Loader?

To start a skid loader, first ensure that the machine is in neutral. Insert the key and turn it to the ‘start’ position. Check that all safety features are engaged before starting the engine. Once running, let it warm up for a few minutes before operation.

What Safety Gear Do I Need For Operating A Skid Loader?

When operating a skid loader, wear appropriate safety gear including a hard hat, safety glasses, and steel-toed boots. Hearing protection is also recommended due to noise levels. High-visibility clothing can help others see you on the job site. Always prioritize your safety while working.

How Do I Operate The Controls Of A Skid Loader?

Skid loaders typically have two joysticks for control. The left joystick controls the movement of the machine, while the right joystick operates the loader arms and bucket. Familiarize yourself with the functions before operating. Practicing in a safe area can help improve your skills.

What Are The Common Uses For A Skid Loader?

Skid loaders are versatile machines used in construction, landscaping, and agriculture. Common tasks include digging, grading, and lifting materials. They are also effective for snow removal and debris clearing. Their compact size allows access to tight spaces, making them highly valuable on job sites.

Conclusion

Operating a skid loader can be a rewarding experience. Mastering the controls enhances your efficiency and safety on the job. Remember to practice regularly and follow safety guidelines. With patience and dedication, you’ll become skilled in no time. Enjoy the versatility and power that a skid loader offers in your projects.