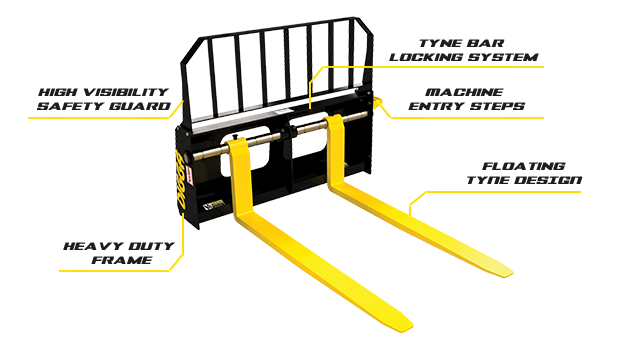

Skid Loader Forks: Enhance Your Lifting Power Efficiently

Skid loader forks are essential attachments for skid steers, enabling efficient material handling. They allow operators to lift and transport heavy loads with ease.

Skid loader forks play a crucial role in enhancing the versatility of skid steers. These forks transform a standard loader into a powerful lifting machine, perfect for construction, landscaping, and agricultural tasks. By attaching forks, operators can effortlessly move pallets, debris, and other materials around the job site.

This attachment not only increases productivity but also reduces manual labor, making projects more efficient. Various fork sizes and styles are available, catering to different lifting needs and applications. Investing in high-quality skid loader forks can significantly improve operational capabilities and streamline workflows in various industries. Choose the right attachment to maximize your skid steer’s potential.

Credit: www.diggausa.com

The Essentials Of Skid Loader Forks

Skid loader forks are vital tools in construction and agriculture. They enhance the capability of skid loaders. These forks help in lifting and moving heavy materials quickly. Understanding their features and types is essential for effective use.

Key Features

- Durability: Made from high-quality steel for long-lasting use.

- Load Capacity: Forks can handle various weights, often up to 2,500 lbs.

- Versatility: Suitable for different tasks, like lifting pallets and debris.

- Easy Attachment: Quick connect systems save time during operation.

- Adjustable Width: Forks can be adjusted for different load sizes.

Types Of Forks Available

| Type | Description | Best For |

|---|---|---|

| Standard Forks | Basic design for everyday lifting tasks. | Pallets and general materials. |

| Heavy-Duty Forks | Thicker steel for heavy loads. | Construction materials and equipment. |

| Adjustable Forks | Width can be adjusted to fit loads. | Various sizes of pallets and crates. |

| Extended Forks | Longer length for reaching further. | High stacks and tight spaces. |

Maximizing Lifting Capabilities

Enhancing the lifting capabilities of skid loaders is vital for efficiency. Proper tools and techniques ensure effective handling of heavy loads. Understanding the right forks can make a big difference.

Proper Fork Selection

Selecting the correct skid loader forks is crucial. Different tasks require different types of forks. Here are key points to consider:

- Fork Length: Longer forks can lift larger loads.

- Fork Width: Wider forks provide better stability.

- Material: Choose durable materials for longevity.

- Weight Capacity: Ensure forks can handle intended loads.

Forks come in various designs:

| Fork Type | Description | Best Use |

|---|---|---|

| Standard Forks | Basic design for general lifting. | Most common applications. |

| Heavy-Duty Forks | Reinforced for heavy loads. | Construction and industrial work. |

| Adjustable Forks | Width can be modified. | Varied load sizes. |

Load Distribution Basics

Understanding load distribution is key for safety and efficiency. Proper distribution prevents tipping or damage. Here are some essential tips:

- Center Load: Keep loads centered on the forks.

- Balance: Ensure even weight on both sides.

- Height: Keep the load low for stability.

- Secure Loads: Use straps or chains if necessary.

Visualizing load distribution helps:

- Draw a line from the load’s center of gravity.

- Ensure it falls within the skid loader’s wheelbase.

Proper lifting techniques and equipment choice lead to safer operations. Maximize your skid loader’s potential with the right forks and knowledge.

Compatibility And Attachments

Choosing the right skid loader forks is essential for efficiency. Understanding compatibility ensures proper function and safety. Different attachments can enhance your loader’s versatility. Explore how to match forks with your loader and learn about attachment mechanisms.

Matching Forks To Your Skid Loader

Forks must fit your skid loader’s specifications. Here are key factors to consider:

- Loader Model: Check manufacturer guidelines.

- Weight Capacity: Ensure forks can handle the load.

- Fork Size: Match the fork length and width to your needs.

Consult your loader’s manual for detailed compatibility. This will help avoid costly mistakes.

Attachment Mechanisms

Different attachment mechanisms exist for skid loader forks. Understanding these helps in efficient use:

| Attachment Type | Description | Advantages |

|---|---|---|

| Universal Quick Attach | Standard mechanism for many loaders | Easy to switch attachments |

| Pin-On Attachments | Secure using pins | Stable and secure |

| Euro/Global Attachments | Common in Europe | Versatile for various tools |

Choosing the right attachment mechanism enhances performance. Always verify compatibility before purchase.

Safety Considerations

Safety is crucial when using skid loader forks. Proper practices ensure safe operation and protect all workers. Awareness of risks helps prevent accidents. Follow these guidelines to enhance safety.

Operating Procedures

- Always wear appropriate personal protective equipment (PPE).

- Ensure the area is clear of obstacles and people.

- Know the weight limit of the forks.

- Keep loads low to maintain stability.

- Use proper lifting techniques to prevent strain.

- Never exceed the rated capacity of the skid loader.

Before starting, perform a safety check:

- Inspect the forks for damage.

- Check the hydraulic system for leaks.

- Ensure all controls are functioning properly.

- Test the brakes and steering.

Maintenance Tips

Regular maintenance keeps skid loader forks in top condition. Follow these tips:

| Maintenance Task | Frequency | Importance |

|---|---|---|

| Inspect forks for cracks | Daily | Prevents accidents |

| Lubricate joints | Weekly | Ensures smooth operation |

| Check hydraulic fluid | Monthly | Avoids malfunctions |

| Tighten bolts | Monthly | Maintains stability |

Keep a maintenance log to track all tasks. This helps identify issues early. Proper maintenance extends the life of your skid loader forks and improves safety.

Material Handling Efficiency

Efficient material handling is crucial for any operation. Skid loader forks enhance this efficiency significantly. They allow you to lift, transport, and stack various materials easily. This capability saves time and boosts productivity on job sites.

Handling Various Materials

Skid loader forks are designed for versatility. They can handle a wide range of materials:

- Wood

- Bricks

- Concrete blocks

- Steel beams

- Palettes

Each type of material requires specific handling techniques. Below is a table summarizing the best practices for each:

| Material Type | Best Handling Technique |

|---|---|

| Wood | Use wider forks for stability. |

| Bricks | Stack bricks in small loads. |

| Concrete blocks | Lift with care to avoid tipping. |

| Steel beams | Ensure forks are rated for heavy loads. |

| Palettes | Align forks properly to avoid damage. |

Workflow Optimization

Using skid loader forks improves workflow significantly. They reduce the time spent on lifting and transporting materials. This leads to faster project completion.

Key benefits include:

- Increased lifting capacity

- Improved maneuverability

- Reduced manual handling risks

- Enhanced safety on site

Investing in high-quality skid loader forks pays off. They streamline operations and ensure effective use of resources. Simplifying material handling means more time for other essential tasks.

Credit: skidsteersdirect.com

Enhancement With Accessories

Skid loader forks are versatile tools. They can lift, move, and stack various materials. Adding accessories enhances their functionality. Accessories transform skid loaders into multi-purpose machines. This makes tasks easier and faster.

Additional Attachments

Many attachments are available for skid loader forks. Each attachment serves a unique purpose. Here are some popular options:

- Bucket Attachments: Perfect for digging and scooping.

- Grapple Attachments: Ideal for handling brush and debris.

- Palettes: Useful for stabilizing uneven loads.

- Snow Plows: Efficient for snow removal tasks.

Using these attachments boosts productivity. Operators can switch tasks with ease. This versatility saves time and effort.

Customizable Options

Customization options make skid loader forks even better. Operators can tailor forks to their needs. Some popular customizable options include:

| Feature | Description |

|---|---|

| Fork Length: | Choose from different lengths for specific tasks. |

| Fork Width: | Wider forks improve stability for larger loads. |

| Material: | Pick between steel or lighter materials for better handling. |

| Attachment Points: | Customize for compatibility with various attachments. |

Customization enhances safety and efficiency. Operators can handle specific tasks effectively. This leads to improved performance on the job site.

Economic Benefits

Skid loader forks offer significant economic advantages. They enhance productivity and reduce costs. Investing in these attachments can lead to substantial savings.

Cost-effectiveness

Skid loader forks are a cost-effective solution for various tasks. They enable quick lifting and moving of heavy materials. This efficiency leads to lower labor costs.

Here are some ways they save money:

- Reduced Labor Expenses: Fewer workers needed for heavy lifting.

- Time Savings: Faster job completion increases overall productivity.

- Versatile Use: Can handle different materials, reducing the need for multiple tools.

Roi On Forks

The return on investment (ROI) for skid loader forks is impressive. Businesses see quick payback from their purchase.

| Factor | Estimated Savings |

|---|---|

| Labor Cost Reduction | $500/month |

| Time Efficiency | $300/month |

| Maintenance Savings | $200/month |

With these savings, many companies recoup their investment quickly. Skid loader forks boost efficiency and reduce operational costs.

Real-world Applications

Skid loader forks are versatile tools used in many industries. They enhance productivity and efficiency. Let’s explore three key areas where skid loader forks shine.

Construction Sites

Skid loader forks are essential on construction sites. They help move heavy materials quickly. Here are some common uses:

- Lifting pallets: Move bricks, tiles, and lumber easily.

- Transporting equipment: Shift tools and machinery around the site.

- Loading trucks: Quickly load materials for transportation.

These forks save time and reduce labor costs. They allow for safe and efficient handling of materials.

Agricultural Uses

Agriculture benefits greatly from skid loader forks. Farmers rely on them for various tasks. Here are some examples:

- Moving bales: Easily transport hay and straw bales.

- Handling feed: Shift large quantities of animal feed.

- Loading produce: Quickly load harvested crops onto trucks.

Using skid loader forks improves farming efficiency. They make heavy lifting tasks easier and safer.

Landscaping Projects

Skid loader forks play a vital role in landscaping. They assist in various tasks, making projects smoother. Some applications include:

- Moving soil: Easily transport soil and mulch.

- Handling rocks: Shift large stones for landscaping designs.

- Loading debris: Quickly clear away waste materials.

These forks enhance the speed and quality of landscaping work. They help create beautiful outdoor spaces efficiently.

Credit: www.skidsteerattachmentdepot.com

Frequently Asked Questions

What Are Skid Loader Forks Used For?

Skid loader forks are essential attachments for moving heavy materials. They are designed to fit skid steer loaders, allowing operators to lift and transport pallets, debris, and other loads efficiently. This versatility makes them ideal for construction sites, landscaping, and agricultural tasks.

How Much Weight Can Skid Loader Forks Lift?

The lifting capacity of skid loader forks varies by model. Most forks can handle loads between 1,000 to 3,000 pounds. It’s essential to check the specifications of your skid loader and forks to ensure safe lifting. Overloading can lead to equipment damage or safety hazards.

Are Skid Loader Forks Adjustable?

Yes, many skid loader forks come with adjustable features. Adjustable forks allow users to change the width for different load sizes. This versatility enhances safety and efficiency when handling various materials. Always ensure the forks are locked securely in place before use.

Can I Use Skid Loader Forks For Snow Removal?

Skid loader forks can assist in snow removal tasks. They can lift and move snow piles efficiently. However, for best results, consider using specialized snow attachments like blades or buckets. This ensures effective snow management and maintains the loader’s performance.

Conclusion

Skid loader forks are essential for maximizing efficiency in various tasks. They enhance lifting capabilities and improve productivity on the job site. Investing in high-quality forks can significantly benefit your operations. Choose the right attachments for your skid loader to ensure you get the most out of your equipment.

Make the smart choice today!