Standard Skid Size: Optimize Your Warehouse Space Now!

The standard skid size is typically 48 inches by 40 inches. This dimension is commonly used in North America for efficient storage and transport.

Understanding standard skid sizes is crucial for businesses that handle logistics and warehousing. These dimensions facilitate easier stacking, loading, and unloading, which ultimately optimizes space and improves operational efficiency. Using the right skid size can prevent damage during transport and ensure that products are securely stored.

Various industries adopt these dimensions for compatibility with equipment like forklifts and pallet jacks. Knowing the standard skid size helps companies streamline their supply chain management. This knowledge can also assist in reducing costs and enhancing productivity, making it a vital aspect of logistics strategy.

Introduction To Skid Sizes

Understanding skid sizes is crucial in logistics and warehousing. Skids are flat structures used for moving goods. They play a vital role in storage and transport efficiency.

The Role Of Skids In Warehousing

Skids are essential in a warehouse setting. They provide a stable base for products. Key benefits of using skids include:

- Space Efficiency: Skids maximize storage space.

- Easy Movement: Forklifts can easily transport skids.

- Damage Prevention: Skids protect goods from floor damage.

Skids come in various sizes. The standard skid size is 48″x40″. This size is widely accepted in the industry.

Comparing Skids And Pallets

Skids and pallets are often confused. Both serve similar purposes but have distinct differences:

| Feature | Skids | Pallets |

|---|---|---|

| Structure | Two bottom runners | Four-way entry |

| Weight Capacity | Usually heavier | Varies by type |

| Material | Typically wood or plastic | Wood, plastic, or metal |

| Usage | Ideal for heavy loads | Versatile for various goods |

Choosing between skids and pallets depends on needs. Skids are better for heavy items. Pallets offer versatility for different goods.

Common Skid Dimensions

Understanding common skid dimensions is essential for efficient shipping and storage. Standard sizes help streamline logistics. Knowing these dimensions ensures your goods fit properly on pallets and in transport vehicles.

North American Skid Standards

In North America, the most common skid size is 48 x 40 inches. This size is widely used in industries. Here are some popular dimensions:

- 48 x 40 inches – Standard size, often used for pallets.

- 42 x 42 inches – Common in beverage industries.

- 48 x 48 inches – Used for larger items and heavy loads.

These dimensions help standardize shipping methods. They also reduce handling errors.

International Skid Size Variations

Internationally, skid sizes differ. Each region has its own standards. Here are some common international dimensions:

| Region | Dimensions (inches) |

|---|---|

| Europe | 47.2 x 31.5 |

| Asia | 39.4 x 31.5 |

| Australia | 48 x 40 |

Different regions have unique needs. Understanding these variations helps in global shipping. It also improves compatibility in international trade.

Benefits Of Standardizing Skid Sizes

Standardizing skid sizes brings many advantages. It improves efficiency and safety in warehouses. Companies save time and reduce costs. Here are some key benefits:

Improved Storage Efficiency

Standard sizes maximize storage space. They allow for better stacking and organization. Here are some benefits:

- Uniformity helps in utilizing vertical space.

- Easy identification of skids enhances retrieval speed.

- Standard sizes fit perfectly in storage racks.

Efficient storage means more products in less space. This leads to reduced overhead costs.

Enhanced Material Handling

Standard skid sizes improve material handling processes. Workers can move materials more easily. This reduces the risk of accidents. Key advantages include:

- Compatibility with forklifts and pallet jacks.

- Faster loading and unloading times.

- Streamlined inventory management.

Easy handling increases productivity. Workers spend less time moving materials. This saves energy and boosts morale.

| Benefit | Description |

|---|---|

| Maximized Space | Standard sizes allow for better use of storage areas. |

| Improved Safety | Uniform skids reduce handling errors and accidents. |

| Cost Savings | Fewer resources are spent on storage and handling. |

Warehouse Space Optimization

Efficient warehouse space optimization is crucial for any business. It helps to maximize storage, reduce costs, and improve productivity. Standard skid sizes play a key role in this process. Proper use of skids can transform how you utilize your warehouse space.

Maximizing Vertical Storage

Vertical storage is an excellent way to save space. Using standard skids allows you to stack products safely. Here are some tips to maximize vertical storage:

- Use Racks: Install adjustable racks for flexibility.

- Stacking Height: Know your skid’s weight limit before stacking.

- Clear Aisles: Ensure aisles are wide enough for safe access.

- Forklift Access: Choose skids that fit your forklift’s reach.

Vertical storage helps you store more goods in a smaller area. This approach improves workflow and reduces clutter.

Layout Configurations For Skids

Choosing the right layout configuration is essential. Different configurations can enhance space usage and efficiency. Here are some common configurations:

| Configuration Type | Description | Best For |

|---|---|---|

| Block Stacking | Stacks skids directly on top of each other. | Heavy, uniform items. |

| Selective Racking | Access to each skid without moving others. | Diverse product range. |

| Drive-In Racking | Forklifts drive into racks for access. | High-density storage. |

Selecting the right layout will depend on your products. Evaluate your needs carefully. The right configuration can lead to better organization and quicker access.

Material Selection For Skids

Selecting the right material for skids is crucial. It affects durability, cost, and performance. Two common materials are wood and plastic. Each has its own benefits and drawbacks.

Wood Vs. Plastic Skids

Wood and plastic are popular choices for skids. They each offer unique advantages.

| Feature | Wood Skids | Plastic Skids |

|---|---|---|

| Cost | Generally cheaper | Usually more expensive |

| Weight | Heavier | Lighter |

| Environmental Impact | Biodegradable | Recyclable |

| Resistance to Moisture | Prone to rot | Water-resistant |

Wood skids are strong and cost-effective. They can handle heavy loads. However, they can rot and warp over time. Plastic skids resist moisture and are lighter. They are also more expensive.

Durability And Load Capacity

Durability is vital for skids. It determines how long they last. Load capacity is equally important. It impacts how much weight they can carry.

- Wood Skids:

- Can support heavy loads.

- Durability decreases in wet conditions.

- May need regular maintenance.

- Plastic Skids:

- Can support various loads.

- Last longer in harsh conditions.

- Requires little to no maintenance.

Choose wood skids for cost-effectiveness. Opt for plastic skids for durability. Consider the environment and your specific needs. Make an informed decision based on these factors.

Custom Skid Solutions

Custom skid solutions offer flexibility in handling and transporting goods. They cater to the specific needs of businesses. Standard sizes might not fit every requirement. Custom skids can enhance efficiency and organization.

When To Consider Custom Sizes

Choosing custom skids is vital in certain situations. Consider custom sizes when:

- Your product dimensions are unusual.

- You require special weight capacities.

- Standard skids do not fit your storage space.

- You need enhanced safety features.

- Your products require specific handling methods.

Custom skids can save time and reduce damage. They ensure that your items remain secure during transport.

Impact On Warehouse Operations

Custom skids can significantly improve warehouse operations. Here are some benefits:

| Benefit | Description |

|---|---|

| Space Optimization | Custom sizes fit perfectly in storage areas. |

| Improved Safety | Custom skids reduce the risk of accidents. |

| Enhanced Efficiency | Faster loading and unloading processes. |

| Reduced Damage | Proper fit minimizes movement during transit. |

Investing in custom skids streamlines operations. They can lead to cost savings and better product care.

Regulations And Compliance

Understanding regulations and compliance is crucial for using standard skid sizes. These rules ensure safety and efficiency in various industries. Following these guidelines helps companies avoid legal issues and maintain a good reputation.

Industry Standards For Skids

Different industries have specific standards for skids. These standards ensure safety and compatibility. Here are key organizations that set these standards:

- American National Standards Institute (ANSI)

- International Organization for Standardization (ISO)

- Occupational Safety and Health Administration (OSHA)

These organizations provide guidelines on materials, sizes, and load capacities. Compliance with these standards is essential for operational safety. Below is a table showing common skid sizes and their industry standards:

| Skid Size (inches) | Industry Standard | Typical Load Capacity (lbs) |

|---|---|---|

| 48 x 40 | ANSI | 2,500 |

| 42 x 42 | ISO | 3,000 |

| 48 x 48 | OSHA | 4,000 |

Safety Considerations

Safety considerations are vital for skid use. Proper handling and maintenance reduce accidents. Follow these safety tips:

- Inspect skids regularly for damage.

- Use appropriate lifting equipment.

- Train staff on safe handling techniques.

- Ensure skids are marked with load limits.

Proper training and safety measures enhance workplace safety. Always prioritize safety to protect employees and assets. By adhering to regulations and safety standards, companies can operate efficiently.

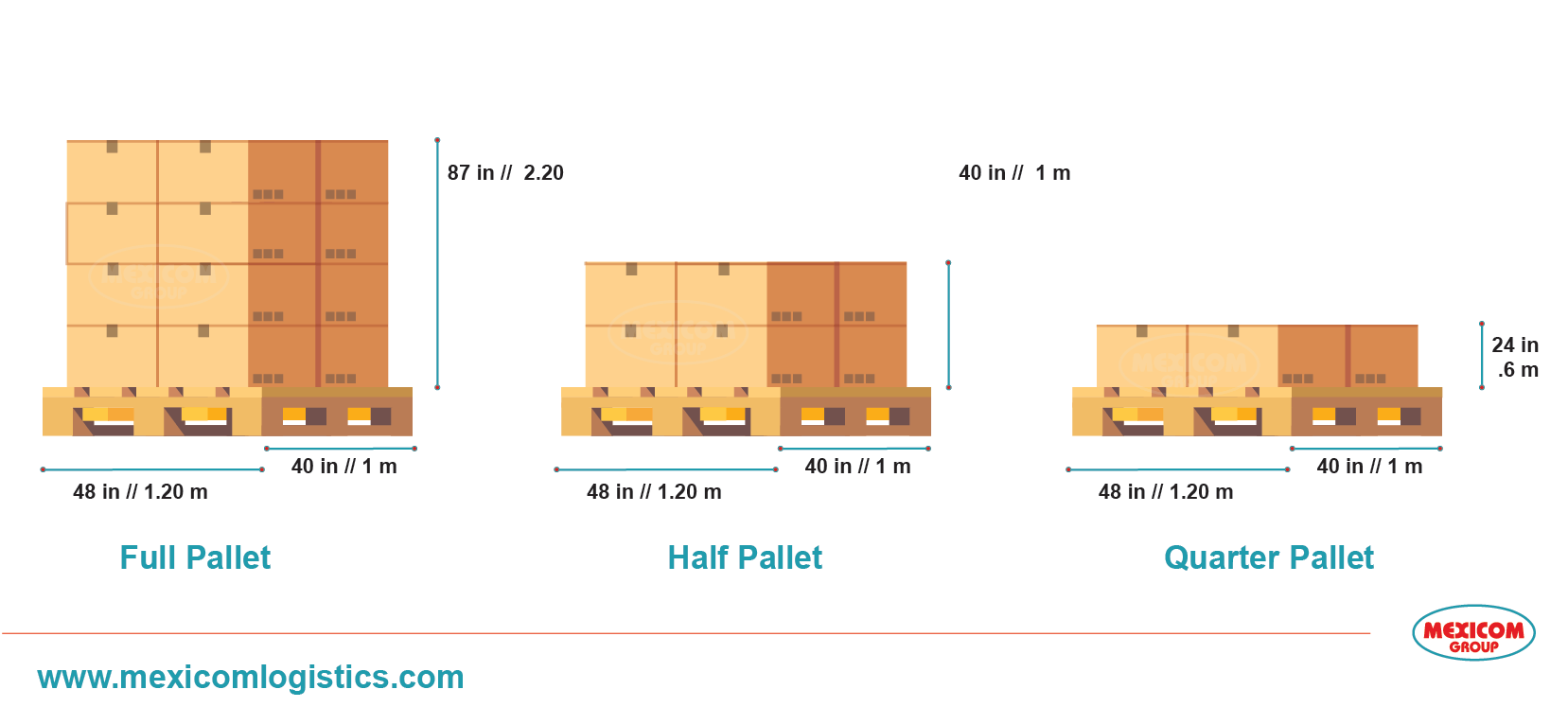

Credit: mexicomlogistics.com

Future Of Skid Usage In Warehousing

The future of skid usage in warehousing holds exciting possibilities. As industries evolve, skids adapt to meet new demands. This evolution focuses on efficiency, technology, and environmental impact.

Technological Advancements

Technological advancements are shaping the future of skids. Here are key innovations:

- Smart Skids: Embedded sensors for real-time tracking.

- Automated Systems: Integration with automated forklifts and robots.

- Data Analytics: Enhanced inventory management through data collection.

Smart skids help reduce human error. They improve efficiency in loading and unloading. Automated systems increase speed and safety in warehouses.

Sustainability In Skid Design

Sustainability is crucial in skid design. The focus is on eco-friendly materials. Here are some sustainable practices:

| Practice | Description |

|---|---|

| Recycled Materials | Using recycled wood and plastic for skid production. |

| Durability | Designing skids that last longer reduces waste. |

| Energy Efficiency | Manufacturing processes that consume less energy. |

Using sustainable materials lowers the carbon footprint. It aligns with global efforts for a greener future. Eco-friendly skids are becoming a standard in modern warehouses.

Case Studies: Successful Skid Optimization

Skid optimization can greatly improve efficiency and reduce costs. Real-world examples show how companies have successfully implemented these strategies.

Real-world Examples

Here are some notable case studies:

| Company | Industry | Skid Size Before | Skid Size After | Cost Savings |

|---|---|---|---|---|

| ABC Manufacturing | Automotive | 1200 mm | 900 mm | $50,000 |

| XYZ Chemicals | Chemical Processing | 1500 mm | 1100 mm | $75,000 |

| LMN Food Supplies | Food Industry | 1000 mm | 800 mm | $30,000 |

Lessons Learned And Best Practices

Companies learned valuable lessons during skid optimization. Here are key takeaways:

- Analyze Load Requirements: Understand load capacity before making changes.

- Test Before Full Implementation: Pilot programs help identify issues early.

- Engage with Experts: Consult engineers for specialized knowledge.

- Monitor Performance: Regular checks ensure continued efficiency.

- Document Changes: Keep records to track improvements and issues.

Implementing these best practices leads to better results. Skid optimization is not just about size. It involves strategic planning and execution.

Conclusion: The Path To Warehouse Efficiency

Understanding standard skid sizes plays a crucial role in warehouse efficiency. Proper sizing leads to better space utilization and easier handling of goods. Let’s recap the key points and discuss the next steps for warehouse managers.

Recap Of Key Points

- Standard skid sizes improve space management.

- Using the correct size minimizes damage during transport.

- Efficient skids streamline loading and unloading processes.

- Standardization helps in inventory tracking.

- Proper skid size enhances safety in the warehouse.

Next Steps For Warehouse Managers

- Evaluate current skid sizes in use.

- Compare with industry standards.

- Train staff on proper handling techniques.

- Implement a system for tracking skid sizes.

- Regularly review and adjust as needed.

Consider creating a table to track performance metrics related to skid sizes.

| Metric | Before Standardization | After Standardization |

|---|---|---|

| Space Utilization (%) | 65% | 85% |

| Damage Incidents | 15 | 5 |

| Time to Load/Unload (mins) | 30 | 15 |

Implementing these steps fosters a more efficient warehouse. Better organization leads to higher productivity and safety.

Credit: www.freightquote.com

Frequently Asked Questions

What Is The Standard Skid Size?

The standard skid size typically measures 48 inches by 40 inches. This size is widely used in North America and is compatible with most forklifts and pallet jacks. It facilitates easy transportation and storage in warehouses, making it a popular choice for various industries.

Why Are Skid Sizes Important?

Skid sizes are crucial for efficient logistics and storage. They ensure that products fit properly on shelves and transport vehicles. Standard sizes help maximize space utilization and streamline operations, reducing costs and improving overall supply chain efficiency.

How To Measure Skid Size Accurately?

To measure skid size, use a tape measure. Measure the length and width from edge to edge. Ensure the skid is placed on a flat surface. Accurate measurements prevent issues during shipping and storage, ensuring compatibility with transport equipment.

Are There Different Skid Sizes Available?

Yes, there are several skid sizes available. While 48×40 inches is standard, other sizes exist for specific applications. Custom sizes can also be created to meet unique needs. Understanding the variety helps businesses select the right skid for their products.

Conclusion

Understanding standard skid sizes is crucial for efficient logistics and storage. Proper dimensions ensure optimal space utilization and safer transportation. By choosing the right skid size, businesses can enhance productivity and reduce costs. Always consider your specific needs to make informed decisions for better operational efficiency.