Top 10 Best Skid Steer Backhoe Attachments: Ultimate Guide

The top 10 best skid steer backhoe attachments include options like the Bradco 610, Titan 12″ Bucket, and ABI Gravel Grader. Each attachment enhances efficiency for digging, grading, and landscaping tasks.

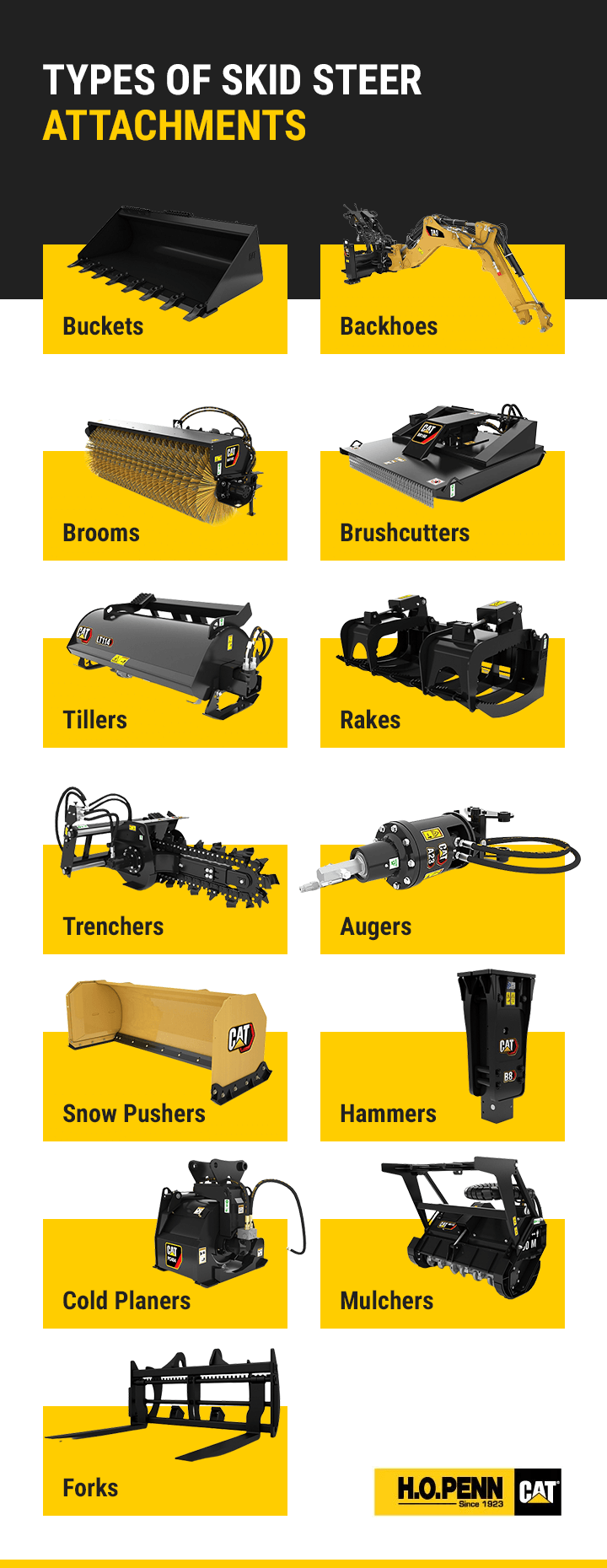

Skid steer backhoe attachments significantly expand the versatility of your skid steer loader. These tools allow for various applications, from digging trenches to grading surfaces. Choosing the right attachment can boost productivity and reduce labor costs. With numerous options available, it’s essential to consider factors such as compatibility, size, and functionality.

Each attachment serves different purposes, making it crucial to select one that fits your specific needs. This guide will help you navigate through the best attachments available, ensuring you make an informed decision for your projects.

Introduction To Skid Steer Backhoe Attachments

Skid steer backhoe attachments are vital tools in construction. They add versatility to skid steers, making them more efficient. These attachments combine the power of a backhoe with the maneuverability of a skid steer. Operators can tackle various tasks easily. From digging trenches to moving materials, they simplify many jobs.

The Role In Modern Construction

Skid steer backhoe attachments serve multiple purposes in today’s construction sites:

- Excavation: Easily dig holes for foundations.

- Trenching: Create trenches for plumbing or electrical lines.

- Material Handling: Move heavy materials around the site.

- Landscaping: Help shape the land for gardens or yards.

- Demolition: Assist in breaking down small structures.

These attachments enhance productivity and save time. They allow operators to complete tasks quickly. The compact design makes them perfect for tight spaces. Thus, they are essential in urban areas.

Benefits For Operators

Using skid steer backhoe attachments comes with numerous advantages:

- Increased Efficiency: Complete tasks faster than with manual tools.

- Cost-Effective: Reduce labor costs by getting more done.

- Multi-Functionality: Perform various tasks with one machine.

- Ease of Use: Designed for simple operation and quick attachment changes.

- Improved Safety: Keep operators secure while working in dangerous areas.

These benefits make skid steer backhoe attachments a smart choice. They boost productivity and safety on job sites. Operators enjoy the ease of handling and versatility these tools provide.

Key Features To Look For

Choosing the right skid steer backhoe attachment is crucial. The right features make work easier and more efficient. Consider these key features to ensure you make a smart choice.

Attachment Compatibility

Attachment compatibility is vital. It ensures the backhoe fits your skid steer. Here are some factors to consider:

- Brand Compatibility: Check if the attachment fits your skid steer brand.

- Size and Weight: Match the backhoe’s size with your skid steer capacity.

- Quick Attach System: Look for a quick attach feature for easy switching.

- Versatility: Choose attachments that can perform multiple tasks.

Hydraulic Performance

Hydraulic performance impacts the efficiency of your backhoe. Strong hydraulic systems improve power and speed. Consider these points:

| Feature | Importance |

|---|---|

| Hydraulic Flow Rate | A higher rate means faster operation. |

| Pressure Ratings | Higher pressure ratings enhance digging strength. |

| Fluid Capacity | More fluid capacity allows for longer use without refilling. |

Look for attachments with robust hydraulic systems. These systems will boost your productivity on any job site.

Top-rated Backhoe Attachments

Finding the best skid steer backhoe attachments can enhance your productivity. These tools allow for efficient digging, loading, and hauling. Their design and functionality make them essential for construction and landscaping tasks.

Brand Reliability

Brand reliability plays a crucial role in choosing backhoe attachments. Trustworthy brands offer durable products. Here are some top brands known for their reliability:

- Bobcat – Known for high-quality attachments.

- John Deere – Offers a wide range of reliable options.

- Cat – Renowned for durable construction equipment.

- CASE – Provides innovative and efficient tools.

Choosing a reliable brand ensures you get the best performance. Their products often come with excellent warranties. This adds peace of mind to your investment.

Customer Reviews

Customer reviews offer valuable insights into backhoe attachments. Users share their experiences with performance and durability. Here’s what to look for:

| Attachment | Rating | Pros | Cons |

|---|---|---|---|

| Bobcat Backhoe | 4.8 | Durable, easy to use | Higher price point |

| John Deere Backhoe | 4.6 | Versatile, reliable | Requires extra maintenance |

| CASE Backhoe | 4.5 | Powerful, efficient | Heavy to transport |

High ratings indicate popular choices among users. Read multiple reviews before making a decision. Look for common praises and complaints to gauge product performance.

Sizing And Fitment Essentials

Choosing the right size and fitment for your skid steer backhoe attachments is crucial. Proper sizing ensures optimal performance and safety. Understanding your skid steer model helps you select the perfect attachment.

Matching To Skid Steer Models

Each skid steer model has specific attachment requirements. Here’s a quick reference table:

| Skid Steer Model | Compatible Backhoe Attachment | Operating Weight |

|---|---|---|

| Bobcat S650 | Bobcat Backhoe Attachment | 3,000 lbs |

| Caterpillar 262D | Caterpillar Backhoe Attachment | 3,200 lbs |

| John Deere 320E | John Deere Backhoe Attachment | 2,800 lbs |

Always check the manufacturer’s specifications. This prevents mismatches and ensures safety.

Ensuring Secure Attachment

Properly securing your backhoe attachment is essential. Follow these steps:

- Align the attachment with the skid steer.

- Engage the locking pins fully.

- Test the attachment by moving the skid steer.

Regularly inspect the attachment points. Look for wear or damage. A secure attachment enhances performance and safety.

Follow these tips for a secure fit:

- Use high-quality pins and bolts.

- Ensure all components are tight.

- Perform routine maintenance checks.

Digging Depth And Reach

Understanding digging depth and reach is vital for skid steer backhoe attachments. These two factors greatly influence how efficiently you can dig and move materials. They determine the type of tasks you can perform and the depth you can reach. Optimal depth and reach enhance productivity and save time.

Importance Of Depth

Digging depth affects the types of jobs you can complete. A deeper reach allows for:

- Excavating foundations

- Trenching for utilities

- Landscaping projects

Different attachments offer varying depths. Here’s a quick comparison:

| Attachment Type | Max Digging Depth |

|---|---|

| Standard Backhoe | 7 feet |

| Extended Reach Backhoe | 10 feet |

| Hydraulic Thumb Backhoe | 8 feet |

Choosing the right attachment based on depth ensures effective operations. It helps prevent delays during projects.

Optimizing For Reach

Reach is crucial for accessing hard-to-reach areas. A longer reach minimizes repositioning of the skid steer. Here are key benefits of optimizing reach:

- Improved efficiency

- Reduced project time

- Better precision in digging

Consider these factors for optimal reach:

- Attachment design

- Weight distribution

- Hydraulic capabilities

Choosing attachments with enhanced reach can significantly impact your project outcomes. Longer reach allows you to work in tighter spaces without moving the machine.

Attachment Versatility

Skid steer backhoe attachments offer incredible versatility. They can tackle various tasks on different job sites. This flexibility makes them essential for construction, landscaping, and farming.

Multi-purpose Use

Many skid steer backhoe attachments have multi-purpose capabilities. Here are some common uses:

- Ditching: Create trenches for drainage.

- Excavation: Dig holes for foundations.

- Landscaping: Move soil, rocks, or debris.

- Paving: Prepare surfaces for driveways.

- Grading: Level ground for construction.

These attachments can switch tasks quickly. Operators save time and increase productivity.

Specialized Attachments

Some attachments focus on specific tasks. Here are a few specialized options:

| Attachment Type | Primary Use |

|---|---|

| Auger | Drilling holes for posts or foundations. |

| Thumb | Grabbing and moving large objects. |

| Hydraulic Breaker | Breaking concrete or asphalt. |

| Rake | Clearing debris or leveling soil. |

| Snow Plow | Removing snow from driveways or roads. |

These specialized attachments enhance performance. They make tough jobs easier and quicker.

Durability And Build Quality

Durability and build quality are crucial for skid steer backhoe attachments. High-quality materials ensure longevity and performance. Investing in robust attachments saves money and time. Let’s explore key aspects of durability.

Materials And Construction

The materials used in backhoe attachments affect their strength. Common materials include:

- High-Strength Steel: Offers excellent resistance to wear.

- Carbon Steel: Lightweight yet durable for better handling.

- Hardox Steel: Known for its toughness and durability.

Construction methods matter too. Welded joints should be strong and secure. Look for:

- Reinforced edges for added protection.

- Quality paint finishes that resist corrosion.

Longevity And Maintenance

Longevity is key for any equipment. Proper maintenance extends the life of backhoe attachments. Follow these tips:

- Regularly inspect for wear and tear.

- Clean attachments after each use.

- Lubricate moving parts to prevent rust.

Investing in quality attachments reduces maintenance needs. Durable attachments perform better and last longer. Choose wisely and ensure your work gets done efficiently.

Hydraulic Requirements

Choosing the right skid steer backhoe attachment depends on hydraulic requirements. Understanding these needs ensures optimal performance and compatibility. Key factors include flow rates and system compatibility. This section will break down these crucial aspects.

Understanding Flow Rates

Flow rates determine how much hydraulic fluid moves through the system. Proper flow rates maximize the efficiency of your backhoe attachment.

- Low Flow: Ideal for light tasks and smaller attachments.

- High Flow: Suitable for heavy-duty attachments and intense work.

Common flow rate ranges for skid steers:

| Type | Flow Rate (GPM) |

|---|---|

| Standard | 10 – 20 |

| High Flow | 20 – 40 |

Check your skid steer manual for recommended flow rates. Matching the flow rate with your attachment ensures smooth operation.

Hydraulic System Compatibility

Compatibility between your skid steer and backhoe attachment is crucial. Hydraulic systems may differ in design and specifications.

- Pressure Ratings: Ensure your attachment can handle the skid steer’s pressure.

- Connector Types: Match the hydraulic connectors for seamless operation.

Key factors for compatibility:

- Check the maximum pressure ratings.

- Identify the hydraulic connector type.

- Review the manufacturer’s specifications.

Always consult with the attachment manufacturer for compatibility advice. This approach prevents potential damage and enhances performance.

Ease Of Operation

Choosing the right skid steer backhoe attachment is essential for productivity. Ease of operation affects efficiency and comfort. Operators need tools that are simple to control. This section explores how various attachments enhance ease of use.

Control And Maneuverability

Good control and maneuverability make work easier. Operators can navigate tight spaces with confidence. Here are key features to consider:

- Responsive Controls: Quick reactions to operator input.

- Compact Design: Fits into smaller areas.

- 360-Degree Rotation: Offers flexibility in movement.

Compare attachments based on control features:

| Attachment Model | Control Type | Maneuverability Rating |

|---|---|---|

| Model A | Joystick | 9/10 |

| Model B | Lever | 8/10 |

| Model C | Foot Pedal | 7/10 |

Operator Comfort

Comfort affects performance during long hours. Attachments with ergonomic designs reduce fatigue. Features to look for include:

- Padded Seats: Provide support during operation.

- Adjustable Controls: Fit different operator sizes.

- Vibration Dampening: Minimize stress on the body.

Here are some attachment models known for operator comfort:

- Model A – Best for padded seating.

- Model B – Excellent adjustable controls.

- Model C – Superior vibration control.

Attachment Maintenance Tips

Proper maintenance keeps your skid steer backhoe attachments in top shape. Regular care extends their life and improves performance. Follow these tips to ensure your attachments remain reliable and efficient.

Routine Check-ups

Regular check-ups are vital for attachment health. Schedule these tasks:

- Visual Inspections: Check for cracks or wear.

- Lubrication: Apply grease to moving parts.

- Bolts and Fasteners: Tighten loose components.

- Hydraulic Hoses: Inspect for leaks or damage.

Perform these check-ups after every use. Regular inspections prevent bigger problems later.

Long-term Care Strategies

Long-term care keeps your attachments functioning well. Consider these strategies:

- Clean After Use: Remove dirt and debris.

- Store Properly: Keep in a dry, sheltered place.

- Protect from Rust: Apply anti-corrosion spray.

- Follow Manufacturer Guidelines: Adhere to recommended maintenance schedules.

Invest time in long-term care. It saves money on repairs and replacements.

Safety Precautions

Using skid steer backhoe attachments can be dangerous. Safety precautions help prevent accidents. Always prioritize safety to protect yourself and others.

Secure Operation

Follow these guidelines for safe operation:

- Wear Personal Protective Equipment (PPE): Always wear a hard hat, gloves, and safety goggles.

- Check Equipment: Inspect attachments before use. Ensure they are in good condition.

- Know Your Surroundings: Be aware of nearby workers and obstacles.

- Use Proper Controls: Familiarize yourself with controls before operation.

- Maintain a Safe Distance: Keep bystanders at least 20 feet away.

Emergency Procedures

Being prepared for emergencies is crucial. Follow these steps:

- Stop Operations: Cease all work immediately if an emergency occurs.

- Assess the Situation: Quickly evaluate the danger.

- Call for Help: Use a phone or radio to contact emergency services.

- Provide First Aid: If safe, administer first aid to injured persons.

- Report the Incident: Document the emergency for future reference.

Staying prepared can save lives. Always follow these safety guidelines.

Credit: www.equipmentshare.com

Cost Considerations

Understanding the cost of skid steer backhoe attachments is crucial. Prices can vary widely based on brand, features, and performance. A well-informed investment leads to better project outcomes.

Investment Analysis

Investing in a skid steer backhoe attachment requires careful thought. Here are key factors to consider:

- Initial Cost: The upfront price of the attachment.

- Durability: High-quality materials last longer.

- Warranty: A solid warranty can save money in the long run.

- Resale Value: Some brands hold value better than others.

Evaluate your budget against these factors. A higher initial cost may save money later.

Cost Vs. Performance

Cost and performance are closely linked. Cheaper options may seem appealing but can lead to issues.

| Attachment Type | Cost | Performance Rating |

|---|---|---|

| Basic Backhoe | $2,000 – $3,000 | 3/5 |

| Mid-Range Backhoe | $3,500 – $5,000 | 4/5 |

| Premium Backhoe | $5,500 – $8,000 | 5/5 |

Choose wisely. A balanced approach between cost and performance ensures better efficiency.

Installation And Removal

Installing and removing skid steer backhoe attachments can be simple. Follow clear steps for efficiency. Proper techniques save time and effort. Let’s explore the process in detail.

Step-by-step Guide

- Prepare the Skid Steer: Ensure the machine is off. Engage the parking brake.

- Position the Attachment: Align the backhoe attachment with the loader arms.

- Connect the Hydraulic Hoses: Match the hoses correctly. This ensures proper function.

- Attach the Pins: Insert the pins to secure the attachment. Make sure they fit snugly.

- Test the Attachment: Start the machine. Check for leaks and movement.

Time And Effort Estimates

| Task | Time Required | Effort Level |

|---|---|---|

| Preparation | 5 minutes | Low |

| Positioning | 3 minutes | Medium |

| Connecting Hoses | 2 minutes | Medium |

| Attaching Pins | 5 minutes | Low |

| Testing | 3 minutes | Low |

In total, the installation takes about 18 minutes. Removing the attachment follows similar steps. Expect similar time and effort for removal.

Credit: www.hopenn.com

Performance Enhancements

Performance enhancements make skid steer backhoe attachments more effective. They increase productivity and reduce downtime. Upgrades can lead to faster job completion. Let’s explore how these enhancements improve your work.

Upgrades And Modifications

Many upgrades exist for skid steer backhoe attachments. Here are some popular options:

- Hydraulic System Upgrades: Boost power and speed.

- Bucket Attachments: Choose from various sizes and shapes.

- Augers: Drill holes quickly and efficiently.

- Thumb Attachments: Enhance gripping capabilities.

Consider these modifications:

| Modification | Benefit |

|---|---|

| Heavy-Duty Frame | Increases durability and strength. |

| Quick Couplers | Speed up attachment changes. |

| Extended Reach | Access hard-to-reach areas easily. |

Boosting Efficiency

Efficiency is key in construction and landscaping. Here are ways to boost it:

- Routine Maintenance: Keep your equipment in top shape.

- Operator Training: Skilled operators work faster.

- Proper Attachment Use: Choose the right attachment for the job.

- Load Management: Avoid overloading for better performance.

Consider these tips for maximum efficiency:

- Use attachments designed for specific tasks.

- Monitor fuel consumption closely.

- Utilize telematics for real-time data.

Operator Training Resources

Training is vital for using skid steer backhoe attachments safely. Operators need to know how to handle machinery effectively. Proper training can enhance productivity and reduce accidents. Here are some excellent resources for operator training.

Available Programs

Many organizations offer training programs for skid steer backhoe attachments. Here are some popular options:

- National Center for Construction Education and Research (NCCER): Provides structured training and certification.

- OSHA Training: Focuses on safety and compliance.

- Local Community Colleges: Often have hands-on training courses.

- Manufacturer Training: Many equipment manufacturers offer specific training programs.

Self-learning Materials

Self-learning materials are great for independent operators. Here are some valuable resources:

- Online Courses: Websites like Coursera or Udemy offer courses.

- YouTube Tutorials: Many experts share tips and tricks.

- Instruction Manuals: Always read the manual for specific machines.

- Simulation Software: Practice skills in a virtual environment.

Using a mix of programs and self-learning materials boosts skills. Operators can become more confident and efficient. This knowledge leads to safer and more productive work.

Warranty And Support

Understanding the warranty and support for skid steer backhoe attachments is crucial. It protects your investment and ensures you receive assistance when needed.

Understanding Coverage

Warranty coverage varies by manufacturer. Most warranties cover:

- Defects in materials

- Workmanship issues

- Specific timeframes, often 1 to 3 years

Some manufacturers offer extended warranties. These may cover additional parts or longer timeframes. Always read the warranty details before purchase.

| Manufacturer | Standard Warranty | Extended Warranty Options |

|---|---|---|

| Brand A | 2 years | Up to 5 years |

| Brand B | 1 year | Up to 3 years |

| Brand C | 3 years | None |

Claiming Support

Claiming support can be straightforward. Follow these steps:

- Review warranty terms.

- Gather necessary documentation.

- Contact the manufacturer’s support team.

- Provide details about the issue.

- Follow their instructions for repairs or replacements.

Keep records of all communications. This can help if disputes arise. Fast and efficient support can minimize downtime.

Check for local dealers. They can assist with repairs and claims. This saves time and effort in getting your equipment back to work.

Accessorizing Your Backhoe Attachment

Accessorizing your backhoe attachment enhances its functionality. The right tools make work easier and more efficient. Explore how to maximize your backhoe’s potential.

Additional Tools

Consider these essential tools for your backhoe attachment:

- Auger: Perfect for digging holes quickly.

- Grapple Bucket: Great for moving large debris.

- Snow Plow: Ideal for clearing snow in winter.

- Trencher: Efficient for digging trenches.

- Hydraulic Breaker: Breaks concrete and tough materials.

Customization Options

Customizing your backhoe attachment boosts its versatility. Options include:

| Customization Type | Description |

|---|---|

| Bucket Size | Select a bucket that fits your projects. |

| Attachment Style | Choose between quick-attach or pin-on styles. |

| Color | Customize the color for branding or preference. |

| Material | Opt for heavy-duty or lightweight materials. |

Explore these options to tailor your backhoe attachment. Choose wisely for better performance.

Credit: www.linkedin.com

Environmental Considerations

Skid steer backhoe attachments play a vital role in construction and landscaping. Choosing the right attachments can impact the environment. Understanding eco-friendly practices and sustainable operations is crucial for minimizing environmental damage.

Eco-friendly Practices

Using skid steer backhoe attachments can be environmentally friendly. Here are some eco-friendly practices to consider:

- Reduce Fuel Consumption: Select attachments that are fuel-efficient.

- Minimize Soil Disturbance: Use attachments that limit soil disruption.

- Recycle Materials: Choose attachments that help recycle and reuse materials.

- Use Electric Options: Consider electric or hybrid attachments.

Following these practices can help protect the environment while working on projects.

Sustainable Operations

Sustainable operations ensure minimal environmental impact. Implement these strategies for better sustainability:

- Regular Maintenance: Keep attachments in good condition to reduce emissions.

- Proper Training: Train operators on eco-friendly practices.

- Efficient Scheduling: Plan projects to avoid unnecessary trips.

- Monitor Usage: Track attachment use to ensure efficient operation.

Sustainable operations lead to a healthier planet. Implement these strategies for a greener future.

Future Trends In Attachments

The future of skid steer backhoe attachments is bright and full of innovation. Rapid advancements in technology will reshape how we work. Attachments will become smarter, more efficient, and user-friendly.

Innovative Technologies

New technologies will drive the evolution of attachments. Here are some key trends:

- Telematics: Real-time data tracking will optimize performance.

- Automation: Automated features will enhance efficiency and reduce labor costs.

- Smart Sensors: Sensors will monitor load and terrain, improving safety.

- Eco-Friendly Options: Sustainable materials will become standard in design.

These innovations will lead to better productivity and reduced downtime. Operators will benefit from easier controls and better safety measures.

Market Predictions

Experts predict significant growth in the attachment market. The following table highlights key market trends:

| Year | Market Growth (%) | Key Drivers |

|---|---|---|

| 2023 | 5.0% | Increased construction activities |

| 2024 | 6.5% | Emerging technologies |

| 2025 | 7.2% | Sustainability focus |

Operators will seek advanced features to maximize efficiency. The demand for versatile attachments will increase, driving innovation.

Case Studies And Success Stories

Explore real-life examples of how the best skid steer backhoe attachments have transformed businesses. These stories showcase the effectiveness and versatility of these tools. From construction sites to landscaping projects, the impact is significant.

Real-world Applications

Many industries benefit from skid steer backhoe attachments. Here are some notable applications:

- Construction: Used for digging foundations and trenches.

- Landscaping: Ideal for moving soil and debris quickly.

- Agriculture: Helps with planting and digging irrigation ditches.

- Road Maintenance: Efficient for pothole repairs and grading roads.

- Utilities: Assists in laying pipes and electrical lines.

Each application demonstrates the attachment’s versatility. Operators can easily switch between tasks.

Business Impact

Companies report significant benefits from using skid steer backhoe attachments. Here are key impacts:

| Impact Area | Before Attachment | After Attachment |

|---|---|---|

| Efficiency | Slow manual labor | Fast, automated digging |

| Cost Savings | High labor costs | Reduced labor expenses |

| Project Time | Long completion times | Faster project delivery |

| Operator Safety | Higher accident risk | Safer operation with machine |

Success stories highlight clear improvements. Businesses save time and money. Operators enjoy a safer work environment.

These case studies show the practical benefits of skid steer backhoe attachments. They enhance productivity across various sectors.

Frequently Asked Questions

What Are Skid Steer Backhoe Attachments?

Skid steer backhoe attachments are tools designed for skid steers. They enhance digging capabilities, making tasks like trenching and excavation easier. These attachments are versatile and can be used for various applications in construction and landscaping. They improve productivity and efficiency on job sites significantly.

How Do I Choose The Right Backhoe Attachment?

Choosing the right backhoe attachment depends on your specific needs. Consider factors like the type of work, soil conditions, and machine compatibility. Attachments come in various sizes and styles, so ensure they fit your skid steer model. Researching brands and user reviews can also help make an informed decision.

Can I Use Backhoe Attachments For Landscaping?

Yes, backhoe attachments are great for landscaping tasks. They can dig holes, remove stumps, and create trenches for irrigation. Their versatility makes them suitable for both large and small landscaping projects. Using a backhoe attachment saves time and effort compared to manual labor.

What Is The Average Price Of Backhoe Attachments?

The average price of skid steer backhoe attachments varies widely. Prices typically range from $3,000 to $10,000, depending on brand and features. Higher-end models may offer additional capabilities and durability. Always consider your budget and the attachment’s intended use when making a purchase.

Conclusion

Choosing the right skid steer backhoe attachment can enhance your productivity significantly. Each option on our list offers unique features tailored to various tasks. Investing in quality attachments will save time and effort on your projects. Equip your skid steer with the best tools and tackle any job with confidence.